Productos

Showing 21–40 of 145 results

SLM pneumatic mounts are made from synthetic rubber and are laterally reinforced with steel springs. The base plate is bored with 4 smooth holes to allow a possible fixing on the ground and the valve allows to inflate the mount in the same way as an automobile tyre.

– Elastomer body (temperature range -30ºC to +180ºC) resitant. To oils, te majority of solvents and natural ageing.

– The top and bottom plates are available in both steel and aluminium.

Download PDF catalog

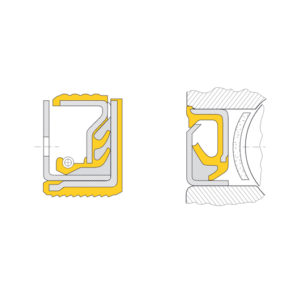

This type of seal has its own friction track.

Its main advantages are:

-reduces the need to grind the shaft,

-treatment of only one part,

-no shaft wear,

– protection of the lip in storage and handling,

– in a bearing, it can serve as a supporting element until it is fitted in the unit.

Download PDF catalog

A void bush is designed to have radial stiffness which are very different at 90° to each other.

Download PDF catalog

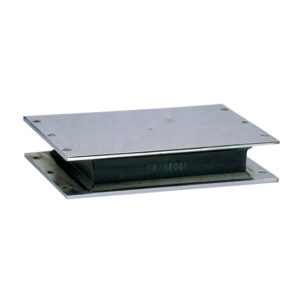

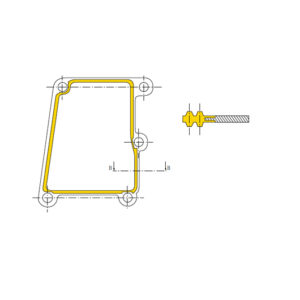

The SANDWICH mounting comprises one or more layers of elastomer bonded to flat, parallel metallic plates. These mountings may be cylindrical or rectangular. They are designed to withstand very high compressive loads. The range of mechanical characteristics is governed by the hardness of the rubber and the number of intermediate metallic plates.

These mountings can support compression from 20 to 100 bars.

The metal plates usually receive a phosphate anti-corrosion treatment.

The elastomer is polychloroprene which provides a high resistance to atmospheric exposure.

Download PDF catalog

– Vertical own frequencies under nominal loads of 5 to 7 Hz.

– Own lateral frequencies under nominal loads of 3 to 6 Hz.

– Stop after 10 mm of displacement. Maximum force on the top of 30 g

Download PDF catalog

Flexible element:

1 Precompressed natural rubber.

2 Bonded metal reinforcing mountings.

3 Precompression band (to be removed after installation).

Flange:

4 Die-cast steel (except 632267 which is cast-iron).

Download PDF catalog

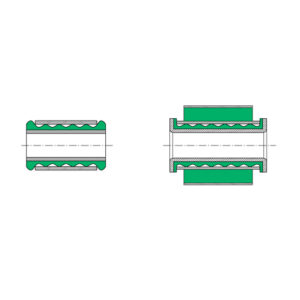

FLUIDBLOC

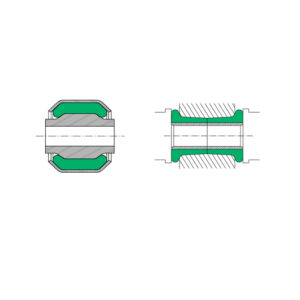

This type of bush is intended to offer minimum resistance to torsion. The elastomer is bonded to only one of the armatures, and a suitable permanent lubricant ensures the lubrication between the elastomer and the second armature ensures a very low torsional resistance.

Seal sare provided at each end to prevent the lubricant from coming out and stop impurities from getting in.

Resistance to axial force is provided by a flange in the elastomer which bears against the side of the outer sleeve, the force being transmitted by a lateral washer.

Download PDF catalog

Teflon has the following advantages:

– a very low coefficient of friction.

– resistance to aggressive products.

Download PDF catalog

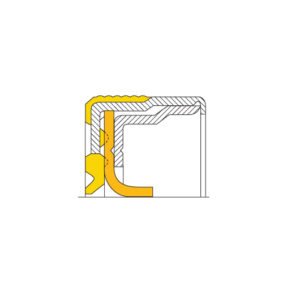

Instead of the metal plate, Paulstra offers a rubberised cover which has the following advantages:

– only a simple shape needs to be machined in the crankcase.

– only one part needs to be fitted to ensure the closure of the crankcase with a perfect seal.

Download PDF catalog

The permitted deflection (40 to 50 mm) of the suspended mass in relation to the mounting base limits reaction under shock.No efficient vibration protection is offerred during shock.

Download PDF catalog

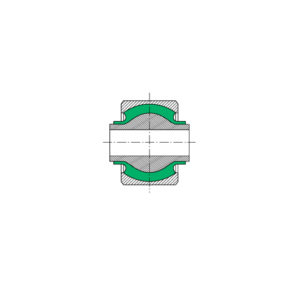

In this bush, the outer sleeve and centre axis are spherical, which enables the bush to resist relatively high radial and axial loads.

Download PDF catalog

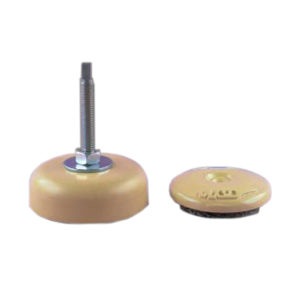

The STABIFLEX mounting comprises a conical rubber section bonded between inner and outer metal parts.

– Centre axis with threaded hole.

– Square (4 holes) or diamond base (2 holes) with clearance hole.

– Bonded natural rubber, anti-slip bead.

– Cup to protect the rubber and distribute the load.

Download PDF catalog

Flexible element:

1 Metallic bobbins linked together by rayon fibres.

2 The whole unit 1 is potted in natural rubber and is hexagonal.

Flange 3: forged steel.

Download PDF catalog

The CUPMOUNT is made of rubber bonded to two metal reinforcements of truncated form.

– Interior reinforcement with tapped hole.

– External reinforcements with square base (4 holes).

Download PDF catalog

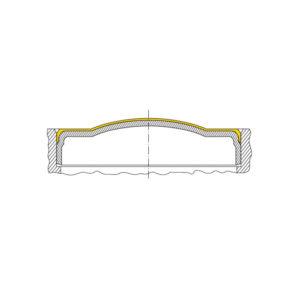

The seal is assured by a beading of elastomer fitted to the inside or the outside of the sheet. The shape of the beading and its attachment to the sheet are designed in such a way that the compression of the elastomer absorbs the faults in the flatness and deformation due to expansion while remaining within acceptable stress constraints.

Download PDF catalog

A load range of between 30 to 1,080 kg, depending on the different configuration and shock specification.

Download PDF catalog

“PRESTRESSED BUSHES” with turned down sides:

For the same dimensions, this type of bush provides a radial load capacity which is superior to that of the classic “prestressed”.

In addition, versions of relatively short length permit conical movement more easily (reduced torque and increased angle).

CONICAL BUSH:

This takes the form of a rubber sleeve whose external surface is a truncated, and which surrounds a cylindrical internal part to which it adheres strongly by high radial expansion.

Assembly in pairs, in a housing made up of two truncated cones placed small end to small end.

By axial pressure, a high compression is created which ensures the external adherence of the rubber and causes lateral cushions to form at each end of the housing. These cushions ensure resistance to axial forces.