Productos

Showing 1–20 of 145 results

These assemblies can withstand high compression loads (along Oz): up to1,000 tons/sq.meter.

They can absorb shear deformation (along Ox and Oy) of 50 to 100% of their height.

Cylindrical or annular type assemblies can also withstand torsional displacement around axis Oz.

In rotation around axes Oy and Ox, these mountings enable angular or low amplitude rotation errors (approximately 1°).

Download PDF catalog

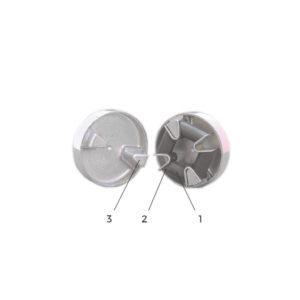

Flexible element:

1. Natural rubber block bonded to.

2. V-shaped metal armatures.

Flange: aluminium or cast-iron.

3. Drive segment.

Download PDF catalog

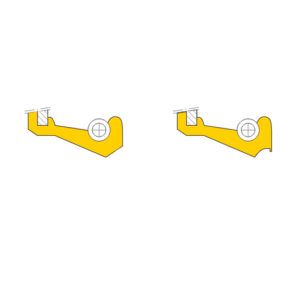

– Metalwork: Mild steel, plated.

– Natural rubber, bonded, cylindrically shaped.

– Welded fixings: 5 styles (single sided threaded stud, single sided threaded hole, double threaded stud, double threaded holes, combination fixing).

In Europe, we often use different screw standards than our french standard.To better satisfy this need, Paulstra has created a new range TRadiaflex Europe. This range is available with the 4 usual welded fixings and with a new fixing: the threaded hole stop.

Download PDF catalog

The efficiency of the ridge increases with its size.

Download PDF catalog

FLEXIBLOC (fig. 1) – FULLY BONDED

This is a bush made up of 2 concentric tubes between which of elastomer is bonded. Under the effect of external forces or torques, the relative movement of the tubes will cause an elastic deformation of the elastomer. By consulting the service conditions, a bush should be chosen which will remain within its elastic operational limits.

SILENTBLOC (fig. 2) – PRESTRESSED

This is a bush made up of 2 concentric tubes between which a ring of “adhérite®” elastomer is inserted by force. Under the effect of external forces or torques, the relative movement of the tubes will cause an elastic deformation of the elastomer. Above a certain value the adherite will slide in the tubes.

Download PDF catalog

In this type of bush, one of the tubes is flanged.

Download PDF catalog

Conical (fig. 1) or spherical (fig. 2) units are used to absorb very high axial loads of up to150 tons.

Angular movement around an axis (Oz in the case of the conical bearing) or a centre of rotation (O in the case of the spherical bearing) are in the order of ± 10°.

Download PDF catalog

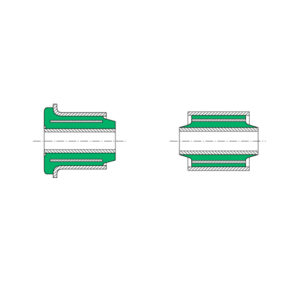

A moulded lip guarantees a better geometrical fit of the sealing lip by eliminating the machining tolerances on:

– the lip angle on the fluid side,

– the distance between the edge of the lip and the axis of the spring,

– the length of the lip (i.e. the distance between the fixing rim and the sealing edge).

Download PDF catalog

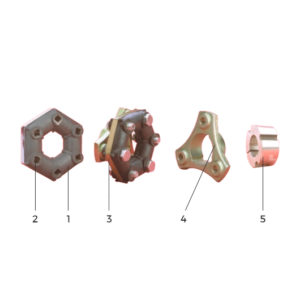

Flexible element 1: polyurethane in the form of a Maltese cross.

Flange 2: cast iron with drive segments 3 supplied unbored (except633054 and 633055).

Variations : For assemblies with a ring or spacer, consult our technical manuals.

Download PDF catalog

– Better than 90% isolation at 1.500 rpm(25 Hz).

– Constant height over wide load range.

– Stabilised characteristics during Service Life.

– Simple to fit.

– 400 hours protection against salt spray*.

– Design.

Download PDF catalog

The EVIDGOM mounting is formed from two thick conical membranes, joined at their bases to create a highly elastic mounting.

There are three variations:

– All rubber EVIDGOM.

– EVIDGOM with bonded fixing.

– EVIDGOM with a diamond or square mounting plate (fixing plate supplied as a separate kit).

Download PDF catalog

Flexible element:

1 Precompressed natural rubber

2 Bonded metal spacers,

3 Precompression band (to be removed after installation).

Flange:

4 Die-cast steel (except 632320 which is cast-iron).

Download PDF catalog

Laminated BUSHES use the same principle as other laminated bearings. Importance is primarily given to radial load capability along Ox and Oy which may be up to 100 tons.

Movement is allowed around an axis Oz or a centre of rotation O. Angular deflection is in the order of 30°.

Download PDF catalog

This type of bush has a thin metallic tube between the internal tube and the external tube.

The object is to have a higher stiffness radially while keeping practically the same stiffness in torsion.

Download PDF catalog

The mini-lip has many advantages:

– Reduced dimensions

The decrease in height and the difference between the internal and external diameters allow type IE seals to be used for applications where only type IO used to be possible. The reduced dimensions also mean less weight.

– Less energy loss due to friction

The radial load is smaller, which leads to a decrease of about 30% of the friction torque, which results in:

– a gain in power for the prime mover.

– less heating.

– Increased life

The decrease in heating due to friction results in a lower temperature, which:

– improves the life of the elastomer.

– slow carbonisation, which causes leaks by producing irregularities and stiffening the lip.

Download PDF catalog

The main role of these mountings is to isolate vibration. A snubber system limits the movement of the suspended mass (10 mm), however the loads developed in this case, are high.

A wide load range from 5 to 320 N depending upon the application.

Download PDF catalog

Flexible element:

1 Precompressed natural rubber.

2 Bonded metal spacers.

3 Precompression band (to be removed after installation).

Flange:

4 Die-cast steel specially bored to fit the separate hub.

5 Universal separate hub (not supplied by PAULSTRA).