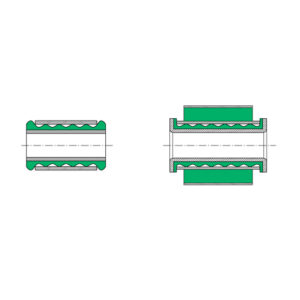

The lamination of a bush also helps to decrease the work rate of the elastomer under high radial loads.

Laminated bushes

This type of bush has a thin metallic tube between the internal tube and the external tube.

The object is to have a higher stiffness radially while keeping practically the same stiffness in torsion.

Download PDF catalog

Related products

“PRESTRESSED BUSHES” with turned down sides:

For the same dimensions, this type of bush provides a radial load capacity which is superior to that of the classic “prestressed”.

In addition, versions of relatively short length permit conical movement more easily (reduced torque and increased angle).

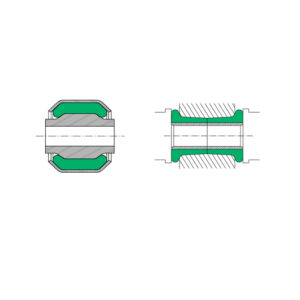

CONICAL BUSH:

This takes the form of a rubber sleeve whose external surface is a truncated, and which surrounds a cylindrical internal part to which it adheres strongly by high radial expansion.

Assembly in pairs, in a housing made up of two truncated cones placed small end to small end.

By axial pressure, a high compression is created which ensures the external adherence of the rubber and causes lateral cushions to form at each end of the housing. These cushions ensure resistance to axial forces.

Download PDF catalog

FLUIDBLOC

This type of bush is intended to offer minimum resistance to torsion. The elastomer is bonded to only one of the armatures, and a suitable permanent lubricant ensures the lubrication between the elastomer and the second armature ensures a very low torsional resistance.

Seal sare provided at each end to prevent the lubricant from coming out and stop impurities from getting in.

Resistance to axial force is provided by a flange in the elastomer which bears against the side of the outer sleeve, the force being transmitted by a lateral washer.

Download PDF catalog

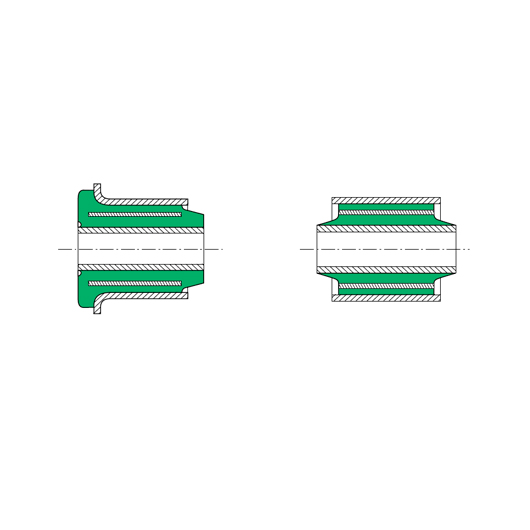

In this type of bush, one of the tubes is flanged.

Download PDF catalog

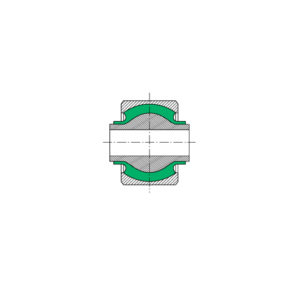

In this bush, the outer sleeve and centre axis are spherical, which enables the bush to resist relatively high radial and axial loads.